Jump to the story of building the Titanic

Introduction

As the largest moveable man-man object of its day, Titanic construction took a little over two years to complete, involving thousands of men and a cost equivalent to over one hundred million in modern day terms. Built at the Harland and Wolff shipyard in Belfast, alongside sister ship Olympic, building Titanic did not go without problems. Read on to discover fascinating facts and figures about the build.

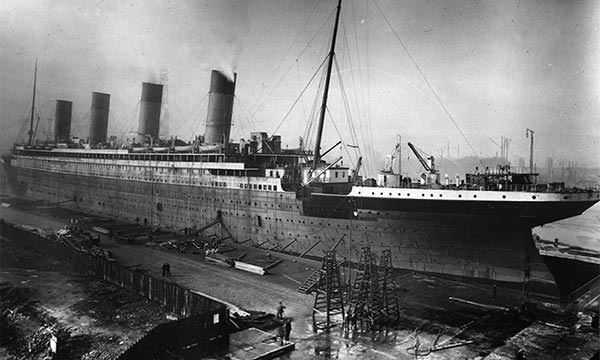

Above: Titanic under construction.

31 March 1909 – the date on which the keel was laid down and the construction of the Titanic commenced.

3 months – the number of months after the keel of Olympic was laid down that Titanic’s keel was laid.

31 May 1911 – the date on which the Titanic launched, entering the Victoria Channel in Belfast Lough from a slipway at the Queen’s Yard of the Harland & Wolff shipyard.

26 months – the length of time it took to build the RMS Titanic, from keel to launch.

How much did the Titanic cost to build?

At the US inquiry into the sinking, Bruce Ismay stated that the cost of building the Titanic was $7,500,000. This was converted into British Sterling at a rate of $5 to £1, with the cost in sterling being recorded as £1,500,000. Based on inflation and modern-day exchange rates, this would put the cost in modern money [?] at something in the region of $166,000,000 (£120,000,000). Interestingly, this is less than the cost of making the 1997 movie Titanic, which was $200,000,000.

401 – the yard number given to the Titanic when her keel was laid down (‘Harland and Wolff Yard No. 401’).

3 – the number of the slipway on which Titanic was built.

228 feet – the height (69 metres) of the gantry built over the RMS Titanic and her sister ship Olympic. Fittingly, it was the largest gantry in the world at that time.

14,000 – the number of men typically employed at the Harland & Wolff shipyard.

15,000 – the approximate number of men employed at the peak of the building work.

How many people built the Titanic?

3,000 – the approximate number of Harland & Wolff shipbuilders who constructed the Titanic.

20% – the percentage of the total Harland & Wolff workforce this number represented.

How many rivets were used on the Titanic?

3,000,000 – the number of rivets used in the construction of the hull. Unlike many ships built at the time, which used strong steel rivets, those used in building the Titanic were a mix of iron and steel, whilst even weaker iron rivets were used in the construction of the bow (the section of the ship that struck the iceberg).

4 – the number of men in a riveting crew.

200 – the number of rivets that a riveting crew could complete per day (assuming dry weather conditions).

15,000 – the number of days work this rate of riveting would have represented for a single crew.

3 months – the intended gap between the completion of Olympic and Titanic. This gap widened as more men were allocated to building Olympic in order to meet her planned launch date.

8 – the number of construction workers killed during the build, from keel laying to launch.

246 – the number of injuries recorded during the build.

Did You Know?

There was an unwritten expectation in shipyards at the time of ‘one death for every £100,000 spent’, so at a build cost of £1.5, the Titanic’s toll was less than the 15 deaths that might have been expected.

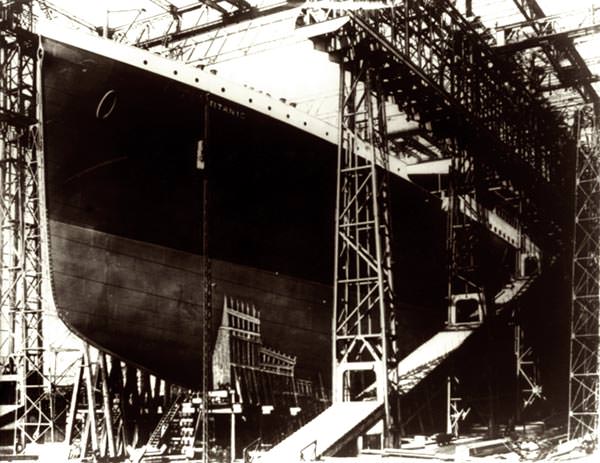

Above: Building the Titanic at the Harland & Wolff shipyard in Belfast.

20 – the number of horses needed to transport the main anchor.

Why was the Titanic built?

Titanic and her sister ships Olympic and Britannic were built to compete with the ocean liners Lusitania and Mauretania. Owned by rivals Cunard, the Lusitania was renowned for her luxury, whilst the Mauretania held the Blue Riband, the unofficial record for the fastest crossing of the Atlantic (a record which remained unbeaten until 1929). White Star Line had decided not to attempt to compete on speed but rather to build larger, more reliable and more luxurious ships than their rivals.

100 feet – the approximate increase in length of Olympic and Titanic over Lusitania and Mauretania.

14,000 – the number of men employed at the Harland & Wolff shipyard.

49 – the average hours worked per week at the shipyard.

£2 – the weekly wage of a Harland & Wolff construction worker.

6 – the number of days worked each week (Saturday was a shorter day, ending early afternoon, and Sundays were not worked).

06.00 am – the time by which yard managers were expected to be on site.

The story of building the Titanic

The construction of the RMS Titanic, an iconic ocean liner, commenced on 31 March 1909. This was a mere three months after the keel of its sister ship, the Olympic, was laid down. The Titanic’s construction unfolded at the Queen’s Yard of the Harland & Wolff shipyard, where it was ceremoniously launched into the Victoria Channel in Belfast Lough on 31 May 1911. The building process spanned an impressive 26 months, signifying a remarkable feat of engineering and human effort.

Funding and resources for this maritime marvel

At the U.S. inquiry into the Titanic’s sinking, Bruce Ismay revealed that its construction cost amounted to $7,500,000. When converted to British Sterling at the time, this equated to £1,500,000. Adjusted for modern-day inflation and exchange rates, the cost would be around $166,000,000 (£120,000,000). Intriguingly, this sum is less than the budget for the 1997 film “Titanic”, which had a production cost of $200,000,000.

Structural specifications and workforce involvement

The Titanic was assigned yard number 401 at its inception. It was constructed on slipway number three, under a gantry that stood 228 feet tall (approximately 69 metres), the largest in the world at that time. Harland & Wolff, the shipyard responsible for the Titanic, typically employed 14,000 men, with the workforce peaking at around 15,000 during the height of the ship’s construction. Remarkably, about 3,000 shipbuilders from Harland & Wolff were directly involved in the Titanic’s construction, representing 20% of their total workforce.

The hull’s construction and the human cost

Millions of rivets were used in the hull’s construction, either from iron or steel, with the former being notably weaker and used predominantly in the bow’s construction – the part that tragically struck the iceberg. A typical riveting crew comprised four men, capable of fixing 200 rivets per day in favourable weather conditions. This rate meant that the riveting task alone would have represented 15,000 days of work for a single crew.

The timeline originally planned for the Titanic was to follow three months after the completion of the Olympic. However, this gap widened due to increased allocation of workers to the Olympic to ensure its timely launch. During the Titanic’s construction, there were eight fatalities and 246 recorded injuries. This was notably less than the shipyard norm of one death per £100,000 spent, which would have projected 15 deaths for the Titanic.

Transportation and logistics

Transporting the Titanic’s main anchor required 20 horses, underscoring the immense scale of the project. The motivation behind the Titanic’s creation was to compete with Cunard’s ocean liners Lusitania and Mauretania. The Lusitania was known for its luxury, while the Mauretania held the Blue Riband for the fastest Atlantic crossing. Instead of vying for speed, White Star Line aimed to surpass these rivals in size, reliability, and luxury. The Titanic and its sister ship, the Olympic, were approximately 100 feet longer than the Lusitania and Mauretania.

Working life at Harland & Wolff

The shipyard boasted a workforce of 14,000 men, each typically working 49 hours per week. A construction worker’s weekly wage was £2, and the workweek spanned six days, with Saturdays being shorter and Sundays not worked at all. Yard managers were expected to be on site by 06:00 am, showcasing the rigorous work ethic that underpinned the Titanic’s construction.

The building of the RMS Titanic was an extraordinary undertaking, marked by significant financial investment, remarkable engineering, and immense human effort. Despite its tragic end, the Titanic remains a symbol of early 20th-century ambition and ingenuity.

More To Explore

If you’ve found these facts on the build interesting, you might also wish to read about the shipyard where Titanic was built and about her ill-fated maiden voyage to New York.